THE PRODUCTION PROCESS

The 10 stages of manufacture

1. Exploitation of the quarry

By means of small controlled detonations, the limestone is extracted, main raw material of the process.

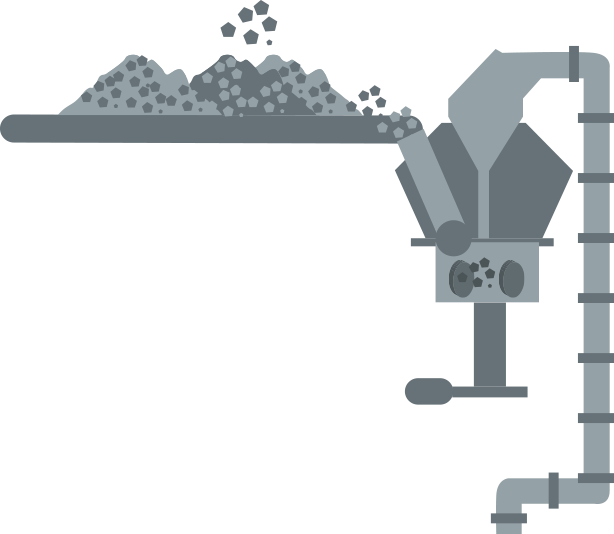

2. Crushing

The limestone is crushed in successive phases until it reaches fragments of about 50 mm.

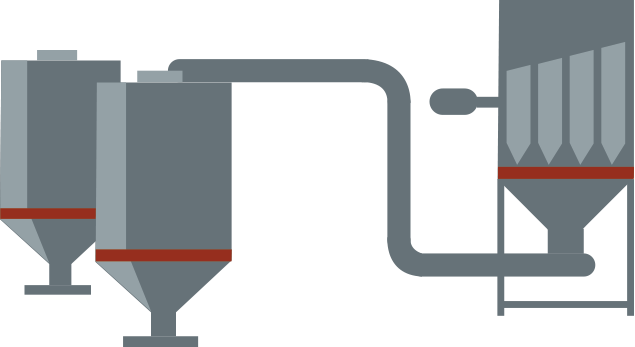

3. Pre-homogenization

Starting from the variable qualities of the stone, a uniform mineral composition is obtained, the raw mix.

4. Storage and grinding of raw meal

With mills of bars or steel balls the ideal granulometry is obtained to form the raw meal.

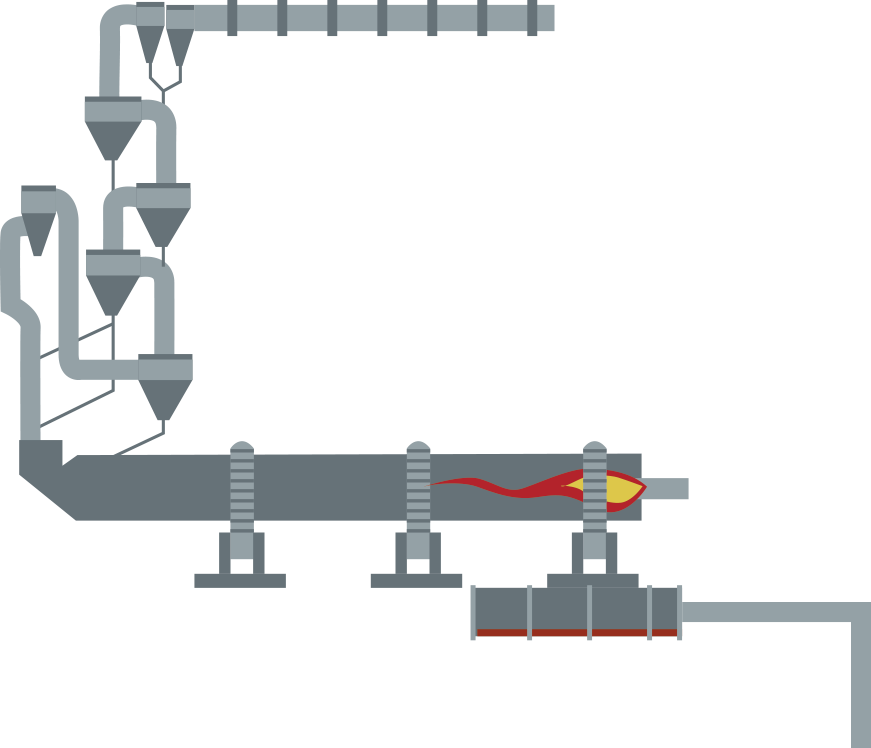

5. Pre-heating

Raw meal passes through the pre-calcination cyclone exchanger, where the residual heat of the furnace gases is used.

6. Rotary kiln: calcination and cooling

Raw meal is the subject of a series of physical and chemical transformations that take place in large rotary kilns:

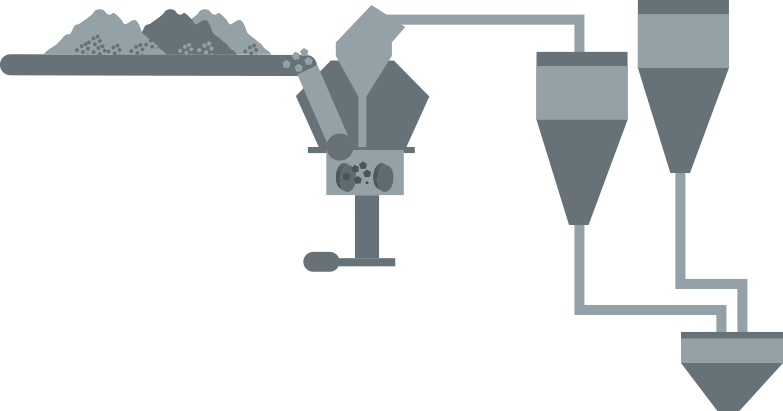

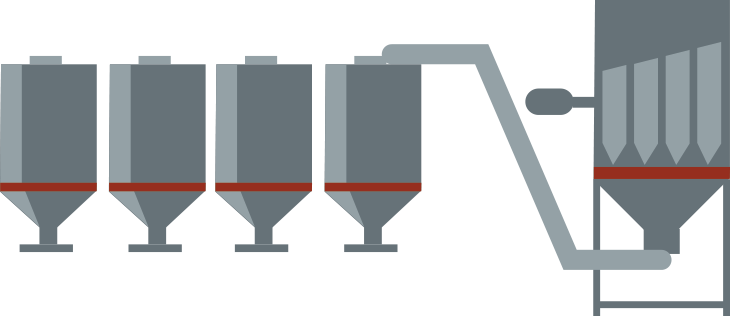

7. Clinker storage

8. Clinker grinding and cement manufacturing

Once the additions, gypsum and other additives have been dosed, the materials are milled and homogenised until the final product is obtained: Portland cement.

9. Cement Storage

10. Packaging or bulk shipment